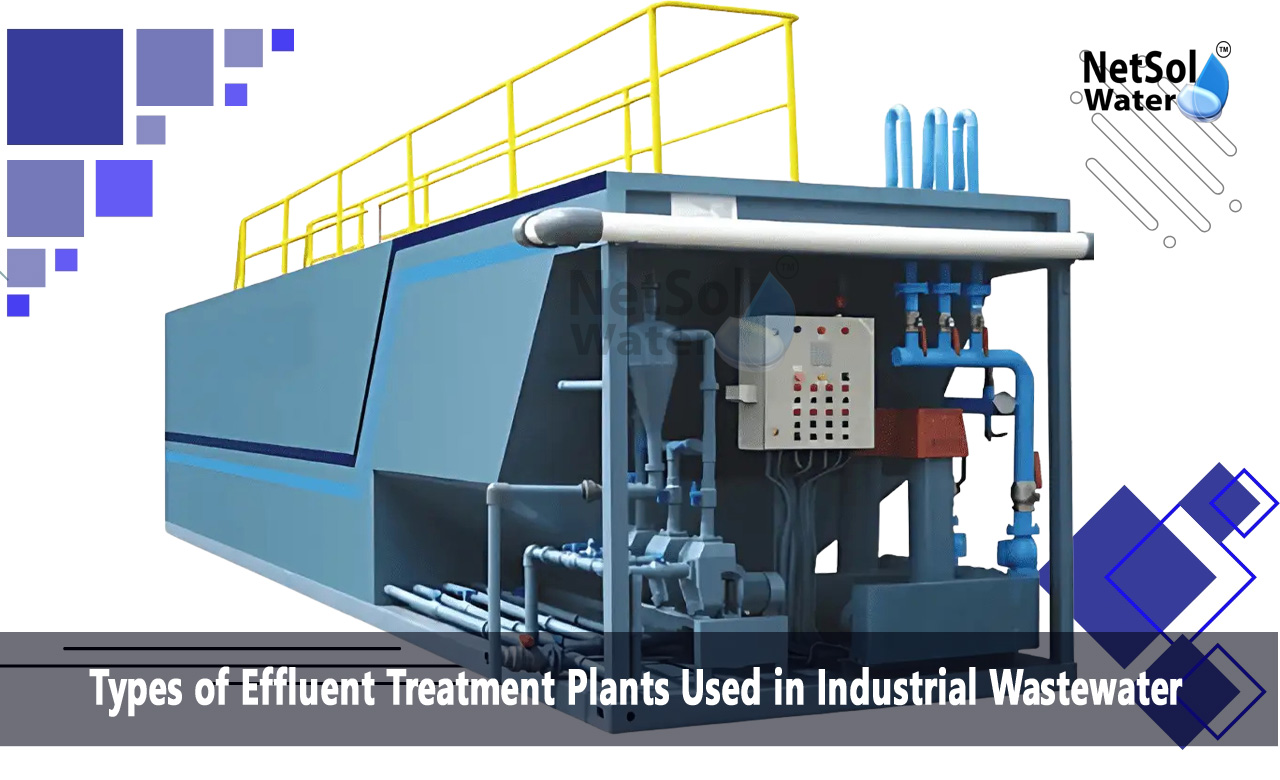

How Many Types of ETP Plants Used in Industrial Wastewater?

Effluent treatment is very much a need & plays an important role for any manufacturing industry. It involves removing the contaminants from industrial wastewater to be recycled again. The following types of effluent treatment plants used in Industrial Wastewater also enable many ways to decrease the solid-liquid waste discharged & also make the water again repurposing. Thus, several types of effluent treatment plants exists for Industrial Wastewater which plays an effective role in cleaning the wastewater to the best purity-level, then also recycling it, & finally set out in the natural world.

However, the various types of ETP Plants for major manufacturing industries to treat their wastewater release will be discussed in brief, let’s have a glimpse at them through this writing.

Types of Effluent Treatment Plants Used in Industrial Wastewater exists as:

1. Food Processing ETP Plants

The food as well as many dairy industries produce a lot of effluent & hence require a lot of water. They frequently produce wastewater that contains chemicals, contaminants, or both toxic & non-toxic substances.

ETP facilitates in their removal & transformation so they may be employed again. ETP for the food business prevents the negative environmental effects of these substances. In order to address the problems with contamination brought on by COD-BOD, ETP Plants execute all of three physical, chemical, along with bio-logical treatment techniques that can process & treat in accordance to the limitations.

2. Effluent Treatment Facilities for Brewing/Winery

High-COD natural water is released by modern brewers. Starch-Carbohydrates, sweeteners, unstable or unsaturated fats, plus ethanol are all readily bio-degradable solvents found in the discharged water. Additionally, wasted grains like wheat/rice & excess yeast are by-products of brewers. This process is made easier by the ETPs Plant installed here, which effectively treats the effluent waste.

3. Medicinal ETP Facilities (Pharmaceutical)

Pharma-ceutical firms discharge wastewater that contains a variety of chemical-solvents, & other harsh compounds that are deadly to both individuals plus animals. The effectiveness of RO attached improves in the dissolution of particulates in pharma ETP by lowering COD, BOD, & TSS. After neutralizing the pH of the industrial wastewater in the neutralizing tank, the colored material is removed & the water is recycled by passing it through an activated carbon-filter.

4. ETP Plants based on Textile Industry

The garment or apparel clothing sector releases wastewater with chemicals applied during prints or dyeing-of clothes. Such water can be treated then repurposed in a natural setting with the aid of textile ETPs. The ETP Plants include a variety of same chemical, physical, & bio-logical therapies.

5. Effluent Treatment Plants installed for Big Slaughterhouses plus Animal Husbandry

ETPs in slaughterhouses or husbandry are completely automated & built to run continuously. Industrial Wastewater from slaughterhouses/husbandry cannot be directly poured into local sewage treatment facilities. Slaughtering-house or animal farms usually constitute of animal stools with urine, besides blood flowing from slaughtering of animals for meat. Suspended solids but predominantly unsafe substances are present in these elements. ETP plants adapt or improve the manufacturing the supplying network along with water recovery process by adding cleaning compounds with manufacturing chemicals.

Also Read: Effluent Treatment Plant Manufacturer

Sequence of Processes Followed One by One in series in These types of ETP Plants Used for Industrial Wastewater

There are various types of Effluent Treatment plants used in Industrial Wastewater but each one follows the same sequence of procedures. Both the main plus secondary phases have been utilized to remove organic waste with large solids. They employ additional chemical processes to improve the quality of industrial wastewater.

1. Primary Stage of treatment:

It involves implementing physical approaches for initial treatment. When industrial wastewater reaches the treatment plant, it contains a lot of particulates that the treatment process is unable to remove. To get rid of these particles, the industrial wastewater reaches a facility designated as the Head-works & passes through enormous screen filters. The solids are then transported to the landfill utilizing a dumpster. This is the only result of wastewater treatment that isn't recycled.

Two massive circular tanks called Primary Clarifiers receive the effluent from the Head-works. The capacity of each of these storage tanks is Six Million gallons. Industrial-Wastewater slows down this way & stays in the tanks for around two hours. Any material suspended in wastewater can therefore either fall to the bottom or float to the top.

2. Secondary Treatment

This treatment Involves apparatus known as Aeration-Basins based on Bio-logical Procedures for treatment. Industrial wastewater is treated bio-logically then flows into big rectangular drums in aeration-basins. As the wastewater slowly passes through a series of chambers, large volumes of air rise up as bubble through the water. In these basins, the wastewater is mixed with "activated sludge," which is made up of hundreds of millions of actively growing single-celled microorganisms.

The wastewater is brown-muddy & it still contains plenty of micro-organisms from the aerator channels when it reaches the two Secondary-Clarifiers. The rotating components of the Secondary-Clarifiers also functions same to drain-out, floating substances from the industrial wastewater effluent.

3. Tertiary Treatment

It involves final level of Filtration plus Disinfection based on Both Physical plus Chemical Procedures. Waste water is as pure as drinking water as it comes out of the secondary clarifiers. Depending on the situation, this water can either go straight to the disinfecting process to produce recycled water or it can go to the Filtration Building.

Conclusion

If you think any types of Effluent Treatment Plants used in Industrial Wastewater treatment required for the Company, always try communicating with the customer support at Netsol Water. Netsol Water is a novel company whose incorporation started in Noida that beautifully designs as well as develops, sets-up, & regularly execute such ETP plants for a variety of manufacturing-enterprises.

The company's many years of knowledgeable expertize alongside deep understanding of constructing ETP water treatment for the various sector establish its status in India's ETP-STP industries. Thus, Netsol Water is a best decision if you've been considering developing a customized unique effluent treatment plant for your industrial manufacturing facilities.

To explore customised commercial RO plants, Industrial RO plants, ETP or STP solutions for your needs in your areas and nearby regions, Contact Netsol Water at: Phone: +91-965-060-8473, Email: enquiry@netsolwater.com