FRP vs SS Industrial RO Plants: Material Comparison

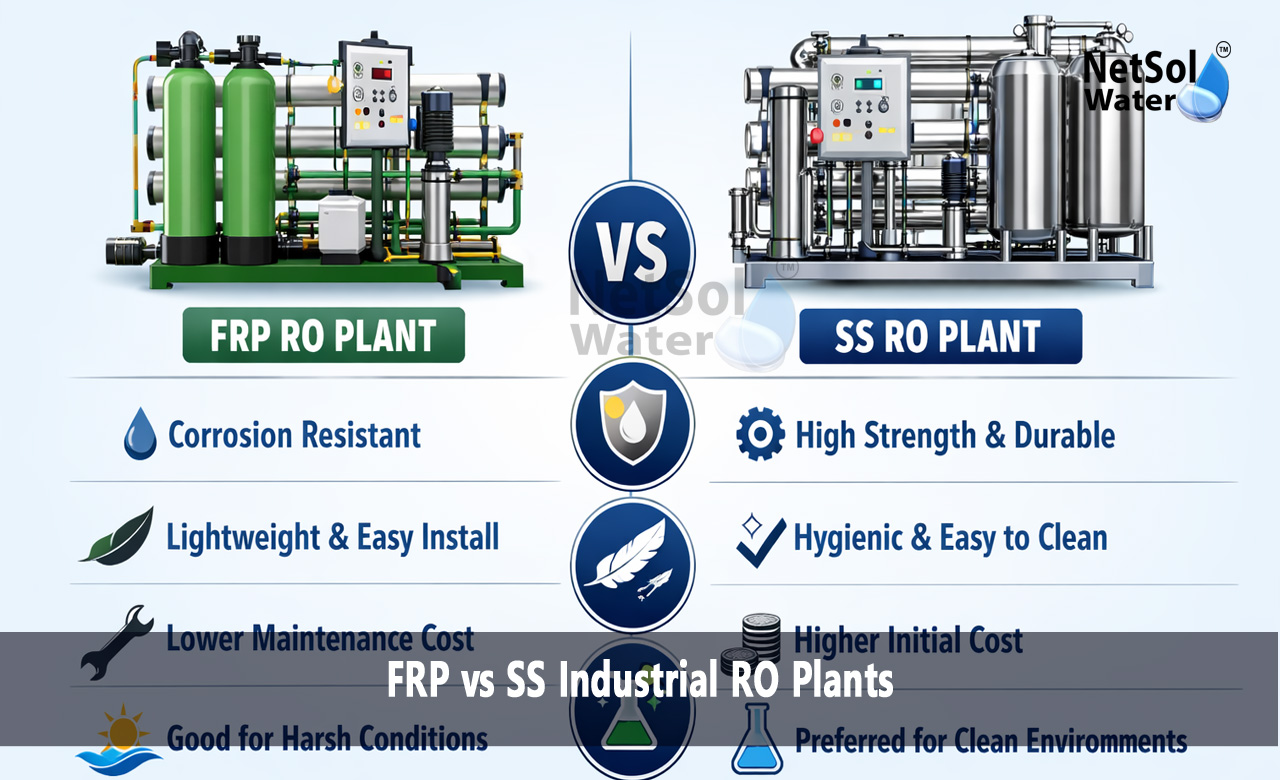

The choice of materials used in long-term use and predictability of industrial reverse osmosis systems is rather significant. As much as design calculations and selecting the membrane take much consideration, the construction material of the RO plant usually influences the corrosion resistance, hygienic factor, the effort of maintenance and the cost of the lifecycle. FRP (Fiber Reinforced Plastic) and SS (Stainless Steel) are the two materials that prevail in the manufacture of RO plants in industries today.

The decision between FRP and SS is not based on cost and appearance only. The behavior of every material under pressure, exposure to chemicals and environmental conditions is different. It is important to understand these differences in order to have the right material when using certain material in industry.

Knowledge of FRP and SS in Industrial RO Plants

FRP is a composite substance formed out of polymer resin and strengthened by glass fibers. It is popular in the pressure vessels, piping, and structural frames because it is resistant to corrosion and is lightweight. Stainless steel on the other hand is a metal alloy which is recognized to be of mechanical strength, hygienic surface and of high durability.

The two materials are applicable in industrial RO plants though their application depends on the quality of the feed water, the operating conditions, regulation policies and the environment of the plant.

FRP and SS Industrial RO Plants

1: Corrosion and Resistance to Chemicals

FRP has a high salinity, aggressive chemical or coastal resistance to corrosion. It is non-rusting and it can be used in environments that contain treated wastewater or high levels of chlorides.

Even though stainless steel is corrosion resistant, it remains susceptible to pitting and crevice corrosion under high-chloride or low-pH environments. Increased grades include SS 316 or duplex steel that enhances resistance at a high cost.

2: Mechanical Handling of Strength and Pressure

Stainless steel offers incomparable mechanical strength and rigidity, and therefore is applicable in high-pressure and high-temperature. It can withstand vibration and mechanical stresses as compared to FRP.

FRP pressure vessels are manufactured to accommodate normal RO operating pressures but are increasingly vulnerable to mechanical impacts and abuse. FRP systems should practice extreme care when you take design safety margins.

3: Hygiene and Cleanability

SS industrial RO plants are also rated high in pharmaceutical, food and beverage industries because they have smooth and non-porous surface and are easy to clean. The stainless steel allows high standards of hygiene and repetitive cleaning with the use of chemicals without the deterioration of the surface.

The FRP surfaces, though being chemically resistant, may become micro-porous with time. This renders them inadequate in environments that are ultra-hygienic, such as those that demand the handling of bacteria.

4: Installation Flexibility and Weight

FRP is much lighter than stainless steel systems and therefore easy to transport and install particularly in skid-mounted or rooftop installations. This saves on load requirements in structures and installation.

SS systems weigh more and need more powerful foundations and lifting solutions and may complicate and raise the cost of installation.

5: Lifecycle Cost Lifecycle Cost Maintenance

FRP industrial RO plants typically have less maintenance expenses in aggressive environments since the plants do not face any threat of rust or surface corrosion. Nonetheless, repairs may be more professional as there may be damage.

Stainless steel systems are more expensive, however, with proper maintenance they have got long service life. Nevertheless, repairs or replacement of damaged parts, which may be due to corrosion, may be costly.

6: Aesthetic and Industrial Acceptance

The SS RO plants have a high look and feel and they are usually utilized in a place where looks and regulatory perception is a concern. FRP systems are functional and are normally used due to their performance than their aesthetics.

Common Selection Mistakes

One of the most common errors is the selection of stainless steel based on appearance only without taking into account the level of chloride of feed water. On the other hand, the choice of FRP in hygienic uses may introduce compliance problems. The other failure mode is to underestimate the environmental exposure like air along the coast, chemical fumes or temperature variations which directly influence the material life.

Conclusion

The operating environment, water chemistry, hygiene needs and lifecycle prospects should motivate the decision of FRP vs SS industrial RO plants as opposed to initial cost. FRP is highly resistant to corrosion, as well as flexible in its installation, and thus it is not prone to aggressive water or outdoor installations. Controlled environments with high requirements of cleanliness offer unparalleled strength, hygiene, and durability of stainless steel.

The selection of materials will be informed to make sure that the RO plant is reliable, compliant, and cost-effective in its entire lifespan.

Do you need an advice or assistance on selecting the best water and waste water treatment unit? We have solutions for all your problems!

Let us know your problem, our experts will make sure that it goes away.

For an assistance or related query,

Call on +91-9650608473 Or write us at enquiry@netsolwater.com